Blog

2026 Top Uses for Stainless Steel Wire Mesh in Industry?

In the ever-evolving industrial landscape, the role of stainless steel wire mesh is becoming increasingly significant. Industry expert Dr. Emily Thompson states, "Stainless steel wire mesh is versatile; its applications are almost limitless." This statement captures the essence of its transformative impact across various sectors.

In manufacturing, stainless steel wire mesh enhances process efficiency and product quality. Its durability and resistance to corrosion make it ideal for both abrasive and chemical environments. Many companies have discovered that using this material leads to cost reductions and improved output. For instance, the food and beverage industry relies on stainless steel wire mesh for filtration and safety standards.

However, there are challenges. Not all industries fully exploit the potential of stainless steel wire mesh. Some remain hesitant due to unfamiliarity. Education and awareness play a crucial role in addressing these gaps. As we explore the top uses of stainless steel wire mesh in 2026, we must consider both its benefits and the areas needing further exploration.

The Role of Stainless Steel Wire Mesh in Filtration and Screening Applications

Stainless steel wire mesh is integral to many filtration and screening processes. According to a report from the International Filtration Society, it accounts for over 40% of the global filtration market. The mesh’s resistance to corrosion enhances its performance in harsh environments. This durability leads to longer service life and reduced replacement costs.

In the industrial sector, stainless steel wire mesh plays a vital role in water treatment facilities. It effectively filters out impurities, ensuring clean water supply. A study by the Environmental Protection Agency shows that systems utilizing stainless steel mesh can improve filtration efficiency by up to 30%. This effectiveness is crucial for maintaining water quality in urban areas.

However, challenges do exist. Not all stainless steel mesh is created equal. Variations in wire thickness can affect screening precision. Some manufacturers produce mesh that doesn’t meet industry standards. These inconsistencies can lead to costly failures in filtration systems. Regular quality checks are necessary to ensure reliability.

2026 Top Uses for Stainless Steel Wire Mesh in Industry

Innovative Uses of Stainless Steel Wire Mesh in Pharmaceutical Manufacturing

Stainless steel wire mesh plays a crucial role in pharmaceutical manufacturing. Its strength and durability make it ideal for producing filter screens. These screens help separate contaminants from raw materials. Consistency is vital in this industry. Inconsistent filtration can lead to product failure. That's a serious concern.

The mesh also finds use in containment systems. These systems ensure safe handling of potent compounds. However, designing these systems poses challenges. Engineers must account for various factors, like mesh thickness. Thin meshes may not provide enough strength. Meanwhile, thicker meshes can impede airflow. Finding the right balance is essential.

Moreover, stainless steel wire mesh is sustainable. It can be reused and recycled. However, industries often overlook this aspect. Many still dispose of used mesh improperly. This issue needs addressing to enhance sustainability efforts. Innovation in design and application of stainless steel wire mesh can lead to more efficient processes. It's time to rethink current practices and embrace new ideas.

Stainless Steel Wire Mesh Solutions for Food Processing Industry Needs

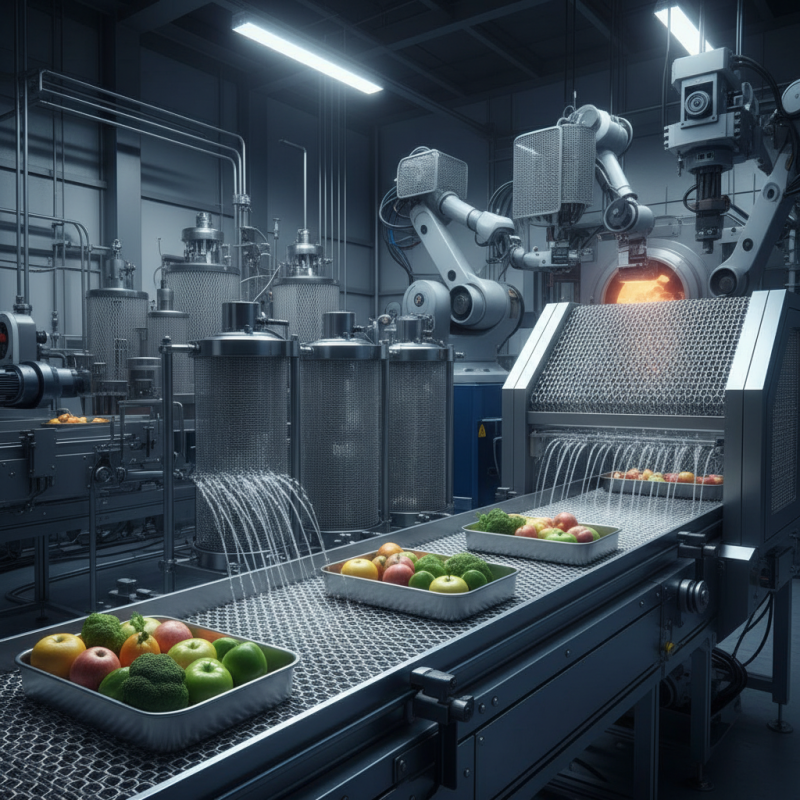

Stainless steel wire mesh is widely used in the food processing industry. Its durability and resistance to corrosion make it an excellent choice. Many facilities utilize it for filters and sieves. This ensures that only pure ingredients are processed. The mesh allows for optimal airflow during drying and baking. These aspects are vital for maintaining food quality.

The mesh's versatility extends to safety applications. It often acts as a barrier, preventing contamination. However, some installations have flaws. For instance, improper tension can lead to sagging, affecting efficiency. Regular checks are necessary to maintain functionality. In addition, cleaning the mesh can become cumbersome. Residue build-up is a common issue that needs addressing.

In food processing, hygiene is critical. Stainless steel wire mesh can provide that, but not without challenges. Small gaps can harbor bacteria, requiring thorough inspections. The mesh should be placed in areas that facilitate easy cleaning. This is often overlooked, leading to potential food safety issues. Continuous improvement in design and application will make stainless steel mesh even more effective.

Applications of Stainless Steel Wire Mesh in Construction and Safety Industries

Stainless steel wire mesh plays a crucial role in construction and safety industries. Its durability and strength make it ideal for various applications. For example, it is widely used in building facades. Architects appreciate its ability to enhance both aesthetics and structural integrity. Imagine a beautiful building facade incorporating stainless steel mesh. It provides a modern look while ensuring safety.

In safety applications, stainless steel wire mesh is key. It is commonly found in safety barriers and security fencing. These installations protect people and property effectively. Consider a school campus surrounded by stainless steel mesh fencing. It not only safeguards students but also allows visibility. This balance of safety and openness is vital.

However, it's important to reflect on some drawbacks. Stainless steel wire mesh can be expensive. Not all projects have the budget for it. Additionally, the installation process may require skilled labor. This can delay project timelines. Despite these challenges, the value of stainless steel wire mesh often outweighs the downsides.

The Impact of Stainless Steel Wire Mesh on Environmental Sustainability Efforts

Stainless steel wire mesh is making waves in various industries. Its contributions to environmental sustainability are notable. For instance, its durability ensures a longer lifespan than traditional materials. This reduces waste in landfills. Many companies opt for stainless steel wire mesh to lower their carbon footprint.

The mesh is often used in filtration systems for air and water. This innovative approach can help purify these essential resources. However, not all industries have adopted this technology yet. Many still rely on less sustainable options. It's important for businesses to reflect on their choices. More environmentally friendly alternatives are available, yet they remain underutilized.

Tips: Consider using stainless steel wire mesh in your next project. It can enhance durability and sustainability. Always research suppliers who prioritize eco-friendly practices. Look for certifications or reviews that highlight their commitment. Every small step can make a difference.